The objective of using RINGER stirrups is to ensure that TMT rebars are held in position so that the columns and beams do not sag. The stirrup can also be placed for transverse reinforcement in a diagonal manner, which helps in avoiding beam cracks that can result from shear failure. You will save construction time and get uniform quality when you purchase Rajuri RINGER stirrups.

Stirrups ready available sizes |

|||||||

| 4 X 10 “ | 7 X 4 “ | 7 X 13 “. | 9 X 12 “ | ||||

| 4 X 13 “ | 7 X 7 “ | 7 X 16 “ | 9 X 15 “ | ||||

| 4 X 16 “ | 7 X 9 “ | 7 X 19 “ | 9 X 18 “ | ||||

| 7 X 3 “ | 7 X 10 “ | 7 X 21 “ | 9 X 21 “ | ||||

Why Rajuri Ringer Stirrups:

- Ready made Stirrups reduce material cutting wastage up to 10%.

- Save up to 20%* on total steel used in a project.

- Rajuri Ringer Stirrups speed up construction leading to faster project completion.

- Eliminate scrap problems and theft incidents.

- Accurately machined Stirrups can strongly and consistently hold together the main reinforcement bars.

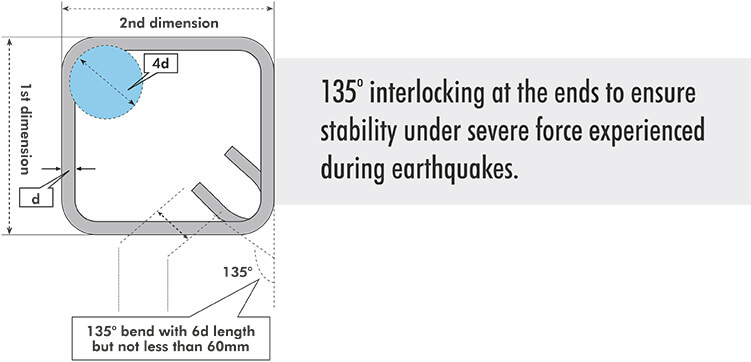

- Stringent adherence to highest quality ensures Stirrups don’t open up even during earthquakes.

- Rajuri Ringer Stirrups bring down labour requirements and related problems with it.

Customized Designs

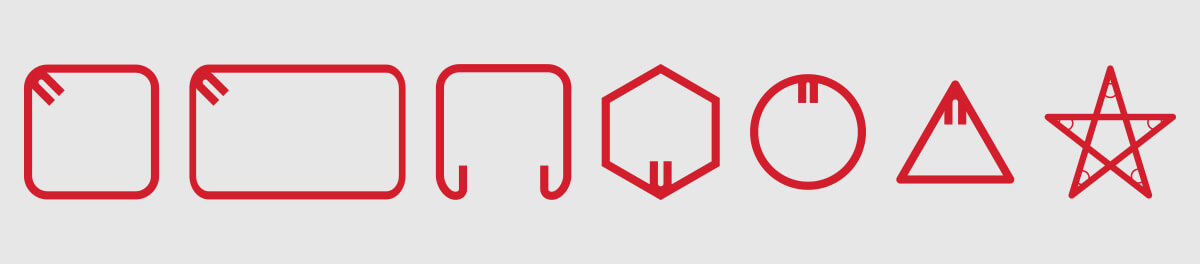

Rajuri RINGER is available in different shapes and sizes to match the designs of pillars, beams, and columns (as per bar bending schedule).

Various Stirrup shapes: rectangle, square, circular, polygonal, U-stirrup

Various Stirrup sizes: 6mm, 8mm, 10mm, 12mm

Another advantage of your project is that your work is speeded up, the stirrups are really dependable, and you don’t have the problem of arranging labour to make them. RINGER stirrups are accurately machined and save you the cutting wastage that often takes place with your material.

Various Type of Stirrups

Rajuri Cut and Bend:

Our services are offered which eliminate wastage in on-site cutting for you and bring you accuracy because of our precise automated cutting and bending. By ordering the bars when you need them, you save the space of stocking them on your site.

It is also faster work to have ready bars supplied instead of requiring an area to cut and bend them on your site. Highly professional Civil Contractors are preferring to accelerate their project work by using our services and reducing on-site labour.

Rajuri Steels have installed a Cutting Line KRB Machine and an Automatic Bending Machine of the latest technology as well as an Automatic Stirrup Bender, which works with computer-controlled cutting and forming operations.

Cut & Bend Advantages:

- Consistent quality and accuracy were achieved through precise cutting and bending at Rajuri Steels, with the help of an automatic rebar processing plant.

- Lower material costs by ordering the precise quantity required.

- The pre-cut bars save your precious material, avoiding wastage if you were to carry out cutting of standard length bars at your construction site.

- Lower warehousing cost – the Cut n Bend bars can be ordered using a ‘just in time’ method of inventory. This also saves the material from overexposure to the elements and to moisture.

- Quicker construction as manual cutting; bending is both unprofessional and slow.

- Labour dependence and pilferage are eliminated.

- Reduced space requirement on-site through the elimination of on-site bar cutting and bending.