Advantages of Continuous Cast Billets :

This is a remarkable product from Rajuri Steels – 500 CRS with longer life, superior resistance to corrosion, easier material handling, and suitable in quake-prone areas. Longer life due to superior pitting corrosion resistance.

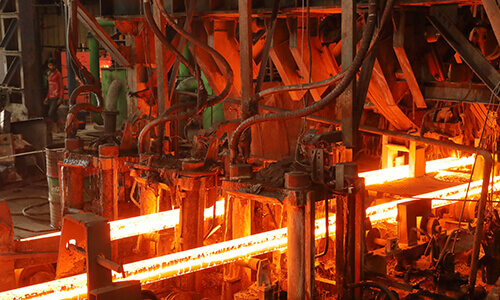

It is a bar produced from corrosion-resistant billets through the continuous casting process (Concast). The billets which have a proper balance of copper, phosphorus, and chromium give the CRS bar its useful properties. The product is manufactured through the ‘Quenching and Self Tempering Process (TMT)’ provided by Thermex, Germany.

Corrosion :

In many regions, structures face a serious threat from corrosion. Corrosion can be caused due to a diverse number of reasons – by coastal breezes, by saline subsoil, by seawater, and by industrial emissions. The threat is so severe that some structures have served only about half of their expected life.

Solution :

CRS is corrosion-resistant steel and has proven to be more effective than earlier treatments such as Cement slurry-coated rebars, Galvanized rebars, and Epoxy coated rebars, etc. In practice, it has been found that steel with corrosion-resistant properties serves better than such treatments and adds to the lifespan of the structure.

In a Rajuri 500 CRS Bar, there is the minimal formation of pores thus oxygen, sulphur dioxide, and chlorine do not permeate through the dense oxide layer. The lower chromium content ensures pitting does not take place. The CRS Bars show higher corrosion resistance than ordinary TMT Bars because of no torsional stress and because its tempered Martensite case repels the attack of corrosion.

Advantages of Continuous Cast Billets :

- No impurities are present

- Homogeneous distribution of various corrosion resistance elements due to purging process

- No surface defects such as blowholes, piping, black holes, flaws, etc.

- Consistency is maintained throughout the length.

Chemical composition of RAJURI STEELS CRS |

|||

| Element | RAJURI CRS | ||

| % C | 0.18 to 0.23 | ||

| % S | 0.045 max. | ||

| % P | 0.045 max | ||

| % S+P | 0.085 max | ||

Dia of Mandrel For Re-Bending |

|||

| Size of Bar (in mm) | RAJURI CRS | ||

| 8 | 7ɸ | ||

| 10 | 7ɸ | ||

| 12 | 8ɸ | ||

| 16 | 8ɸ | ||

| 20 | 8ɸ | ||

| 25 | 8ɸ | ||

| 28 | 8ɸ | ||

| 32 | 8ɸ | ||

Note: ɸ = Diameter Of The Test Piece ( Bar in mm ) |

|||

Dia of Mandrel For Bending |

|||

| Size of Bar (in mm) | RAJURI CRS | ||

| 8 | 5ɸ | ||

| 10 | 5ɸ | ||

| 12 | 5ɸ | ||

| 16 | 5ɸ | ||

| 20 | 5ɸ | ||

| 25 | 6ɸ | ||

| 28 | 6ɸ | ||

| 32 | 6ɸ | ||

Note: ɸ = Diameter Of The Test Piece ( Bar in mm ) |

|||