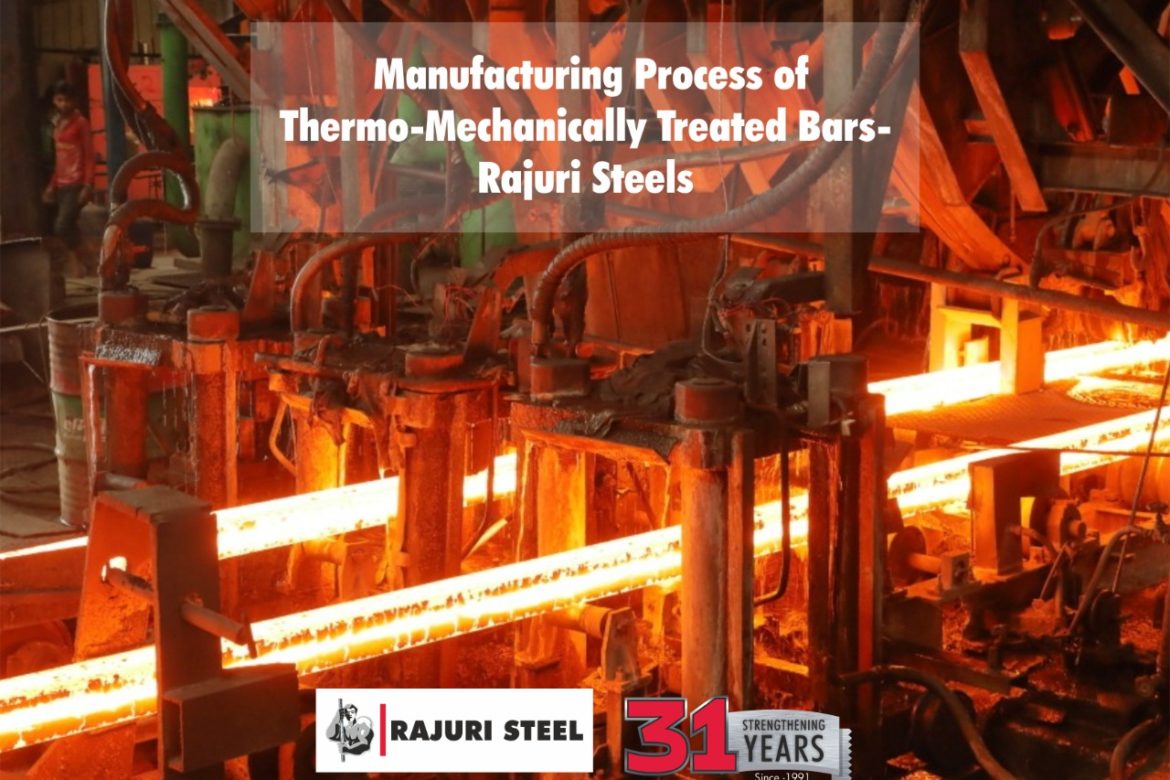

Do You Know The Manufacturing Process of TMT Bars – Rajuri Steels

- TMT bars are one of the essential parts of all types of construction. Did you know what makes TMT bars so flexible and ductile to be considered as one of the integral parts of construction? To know this, we need to understand how the best quality TMT bars are manufactured in India.

TMT Bar stands for Thermo Mechanically Treated bars and passes through a set of processes that determine the flexibility and strength of the TMT Bars. - The quality of TMT bars depends on various factors such as:

The equipment used for the self-tempering and quenching process.

The used material quality.

The rolling mill shapes material.

Steps Involve in the Manufacturing Process of TMT Bars:

- Iron Ore/Raw material to Billet:

The raw material is placed in the furnace and treated with hot gas while in its liquid form. The molten state of iron is pre-processed and converted into steel. The liquid form of steel is then poured into a casting machine to get the billets. At this point, the iron ore gets purified, and all the impurities get accumulated in the form of slag. - Conversion of Billets to steel:

Once the billets attain desired rolling temp it is ejected from the furnace. Then with the help of a rolling conveyor, these billets are made to pass through 1 stand i.e.Roughing stand. Temperature prior to rolling is also monitored by St optical pyrometer. This begins the process of gradual size reduction of billets. Following roughing mill, the size is further reduced in intermediate & finishing Mill. This gradual reduction is an important factor to ensure the finer grain structure of the bar. The rolling continues till the required size is achieved with the help of Roller Bearing Fitted roll, it prevents any unnecessary deformation of the bar. The loop scanners in the flow of the bar ensure a perfectly tensionless rolling process & result in the perfectly round shape of the bar. The surface characteristics of the steel are finalized in this section only. - Thermo Mechanical Treatment:

Thermo Mechanical Treatment is the final step in the manufacturing process of the TMT bar. It involves three sub-steps.

These three essential steps are:

Quenching

Self Tempering

Atmospheric cooling

Quenching: The process of quenching is intended to provide the hardness and ductility to the steel bars and assure the right and desired properties. As the hot rolled steel bars come out from the mill, they enter into a water spray system called ‘Thermex System’. In this process, the temperature of the outer layer of the steel bars decreases rapidly, which leads to hardening it, while the inner core remains hot and flexible. The entire process is called ‘quenching’ of the TMT bars.

Self-tempering: After the quenching process of the bar, the material cools down and the core of the bar is at a higher temperature than the outer surface. The heat is transferred from the core to the outer surface, as a result, the outer structure is get tempered. This causes a flow of temperature from the core to the outer surface area which creates the structure called ‘Tempered Martensite’.

Atmospheric cooling: In this process, TMT bars are put on a cooling bed, where bars are arranged to be cooled at the normal atmospheric temperature, during this austenitic core of the bars turns into a ferrite-pearlite structure. This step makes sure that the tensile strength of the bar develops weldability. During this, the austenitic core of the bars turns into a ferrite-pearlite structure.

- CONCLUSION:

Now you know the making process of the most essential element of your construction structure. These are the processes that follow the manufacturing of quality TMT bars. At Rajuri Steel, we manufacture the best quality TMT bars which meet international standards and ensure the safety of your structures. - For more information please watch the video:

All Comments:

nice article.

Thanks for posting this helpful blog

your blog article very nice. i learn about Thermo Mechanical Treatment process.

Thanks for the nice sharing.