Rajuri Steels: Revolutionizing the India Steel Industry with Top-Notch Products

It is a well-known fact that steel is one of the few materials that can be reused and recycled, holding the potential to power the economy in the future. Especially the TMT bars stand-out as the backbone of every construction industry in India, which are manufactured with a unique metallurgical process known as ‘Thermo Mechanical Treatment’. Standing tall as the epitome of manufacturing a wide range of steel & TMT bars is Rajuri Steels, a highly renowned brand for offering the highest quality products to its customers. For three decades, the company has been committed to the progress of a nation through focus on excellence and quality in steel products. Kailash Loya, Managing Director, Rajuri Steels, asserts, “Our goal is to help build a better world with smarter steel. The conviction entrusted by our valued customers encourages us to scale our production capacity and capabilities to newer heights”.

Products Par Excellence

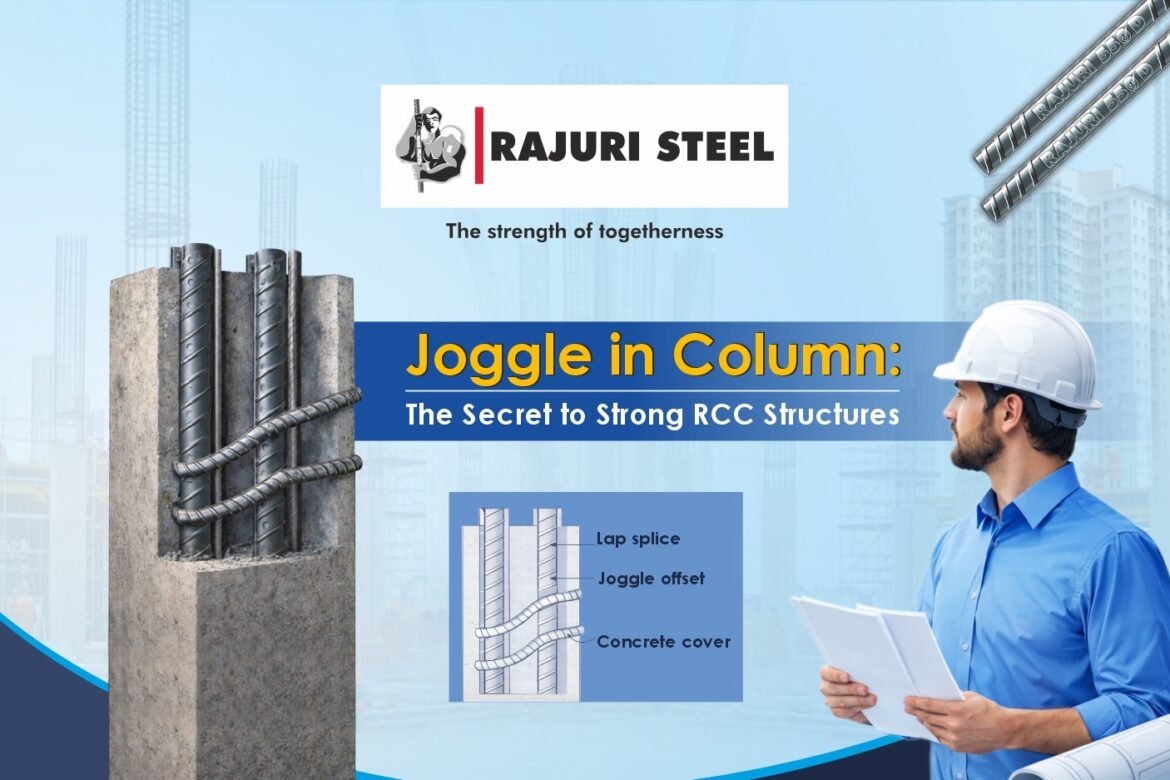

With a wide range of exclusive products, Rajuri Steels always strives to build a stronger foundation for our nation. Having Rajuri 6mm TMT Bar as its flagship product, Rajuri Steels outshines as the first steel plant in India that produces 6mm TMT bars using billets. These rebars have better ductility, superior finish, uniform rib pattern, higher elongation, are cost-effective, and are easy to deploy. The company manufactures steel bars of varying grades including Fe500, Fe500D, and Fe550 in 6mm to 40mm sizes and also offers a wide variety of TMT steel bars of adequate quality which includes Rajuri 500, Rajuri 500CRS, Rajuri 500D Plus, Rajuri Actual Fe550, 6mm TMT Bars, Rajuri Ringer Stirrups, and Binding wires. In fact, Rajuri Steels’ TMT Bars are reputed for their unique ductility, weldability, excellent bonding strength, better mechanical and chemical properties, formability, fire, earthquake, and corrosion-resistant properties.

The steel industry is a very competitive market, and the prices play a huge role in the selection process. Consumers often buy materials by comparing prices, trying to get a bar according to their value for money. Hence, the company is greatly focused and committed to providing premium quality TMT bars at the most affordable prices to its customers. The focus has always been to meet the needs of individual house builders who are building their dream homes within their budgets. Moreover, Rajuri Steels is constantly working to drive innovation in its products by placing R&D at the heart of its operations.

Over the last few years, the market for TMT bars has changed drastically due to technological advancements. Since technology is an integral part of an organization to produce high-quality TMT bars, Rajuri Steels has adopted state-of-the-art technologies across all its processes and products. Furthermore, the company takes utmost pride in outclassing as a pioneer in India for manufacturing high-quality, corrosion-resistant TMT bars using German Thermax technology.

“Over the years, Rajuri Steels’ sustainable growth has been driven by its operational excellence and continuous improvement while it constantly ensures to provide the customers with the best and top-notch products”.

People-Centric Industry

The steel industry is not just about the steelmaking process, but also about its people. Rajuri Steels is a team of professionals with unique talents and diverse backgrounds. Its growth and development have been accelerated by Kailash – a visionary with dynamic directorship. Over three decades of dedication, he has developed an uncommon versatility across different domains such as Production, Sales, and Marketing in the steel industry. His intimate knowledge of processes and trends equips him with a futuristic outlook that sets out a growth trajectory for the company.

Rajuri Steels holds an inclusive culture where every employee feels like they belong and are valued. Its culture is deeply entrenched in its core values of leadership, integrity, customer-centric approach, accountability, and advancements toward excellence. Moreover, the company assures to foster a culture of diversity, innovation, quality management, and employee welfare by maintaining their work-life balance.

Even during the times of COVID-19 crisis, as an organization, Rajuri Steels pledged the responsibility to act in the best interests of its people by taking cautious steps to ensure health and safety in the working environment. All its offices were managed in observance of government guidelines including physical distancing, mask usage, vaccination guidelines and vaccination drives. For employees from other states, the company arranged transport to ensure that they reached their homes safely.

Sustainable Developments

On the note of sustainability, Rajuri Steels has continuously explored opportunities to use renewable energy sources, which is the best way to reduce the impact of climate change. The company will be further integrating its plant with solar panel equipment to generate electricity, thus avoiding wastage of electricity. The company also aspires advancements with sustainability while striving to make steel cleaner and greener. Kailash adds, “We will continue to push boundaries to reduce the carbon footprint of steel through innovation and technology”.

Over the years, Rajuri Steels’ sustainable growth has been driven by its operational excellence and continuous improvement while it constantly ensures to provide the customers with the best and top-notch products. In near future, the company envisions expanding its 25-acre fully automatic facility which will help them to increase the production capacity. Kailash concludes, “We are always striving to deliver the best-in-class products to our customers and are continuously developing our products through our vibrant R & D department. With the aim of building a strong nation, we are expanding our business all over India in the upcoming future”.

All Comments:

The blog beautifully encapsulates the significance of steel, especially TMT bars, in the Indian construction industry. Your mention of the Thermo Mechanical Treatment process gives the reader a deep insight into the intricacies of steel manufacturing.